Hydraulic laboratory with high-performance measuring circuits

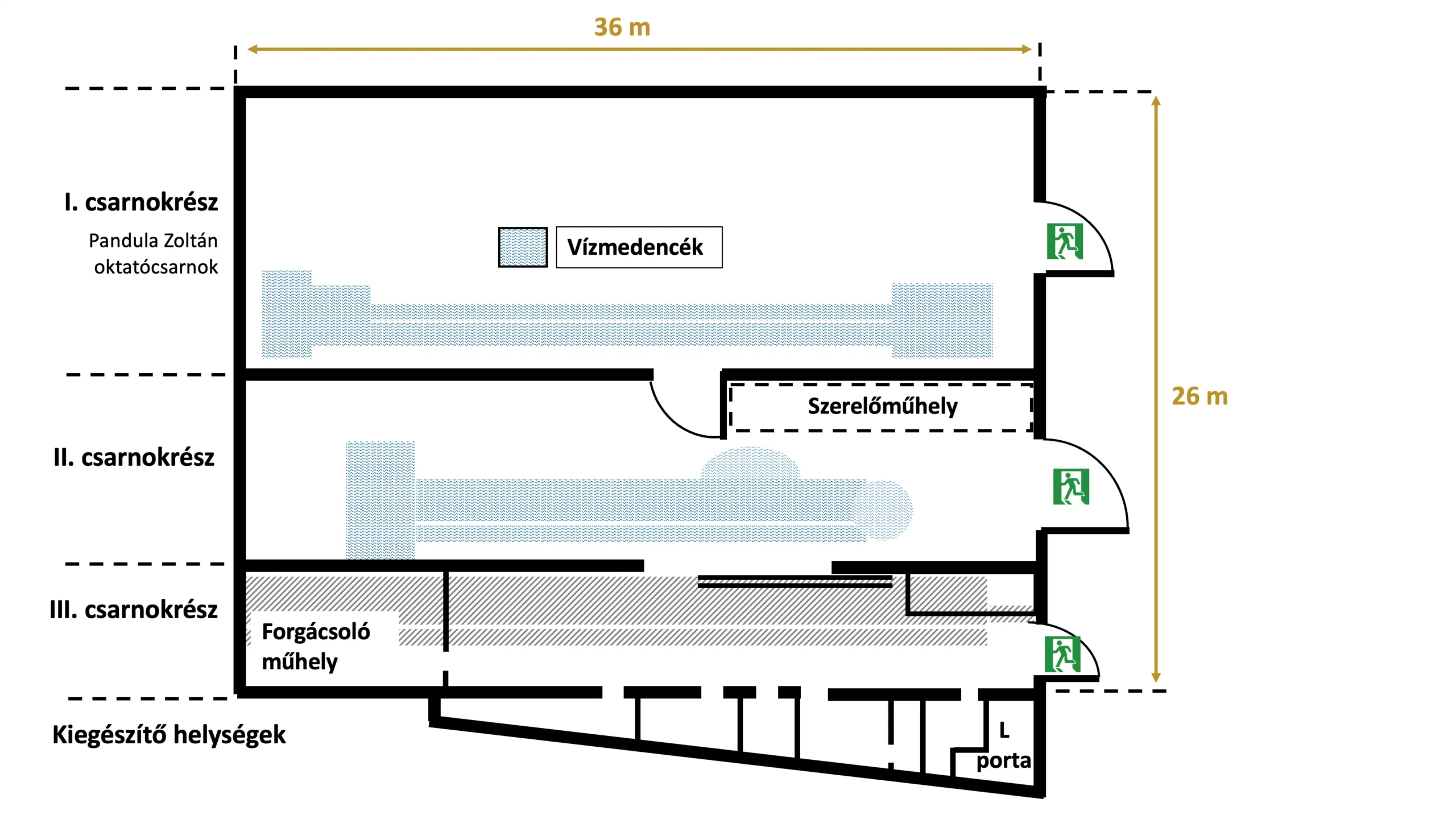

The Laboratory of the Department of Hydrodynamic Systems is located separately from the department offices, in Building L of Budapest University of Technology and Economics. The laboratory covers an area of nearly 1000 m2 and is divided into three main halls. Halls I and III are equipped with measuring systems used for practical training of BSc and MSc students, as well as for carrying out a significant part of the department’s research. Hall II contains our mechanical workshop and also serves as the home of the BME Solar Boat Team, a student competition team.

General properties

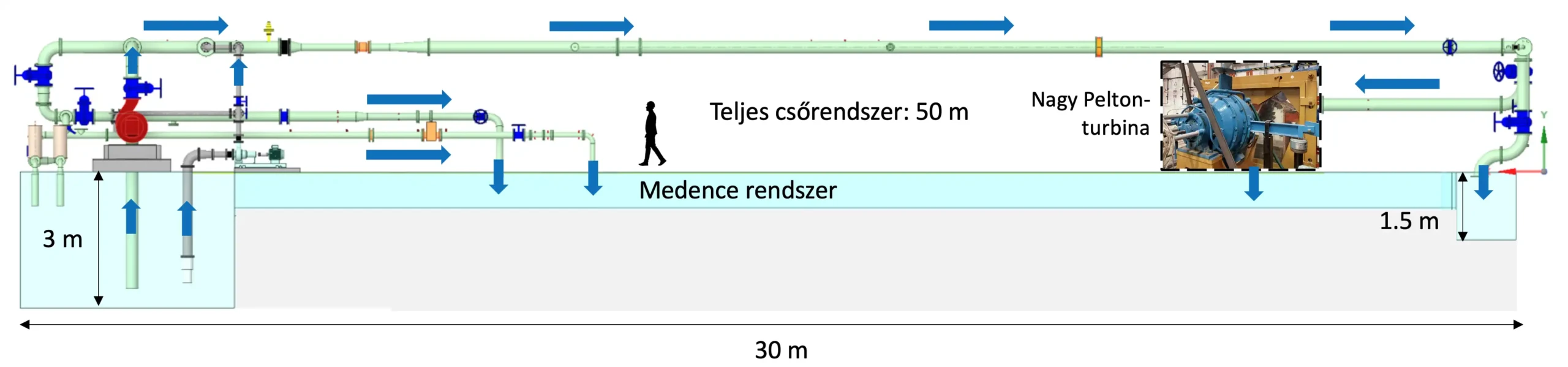

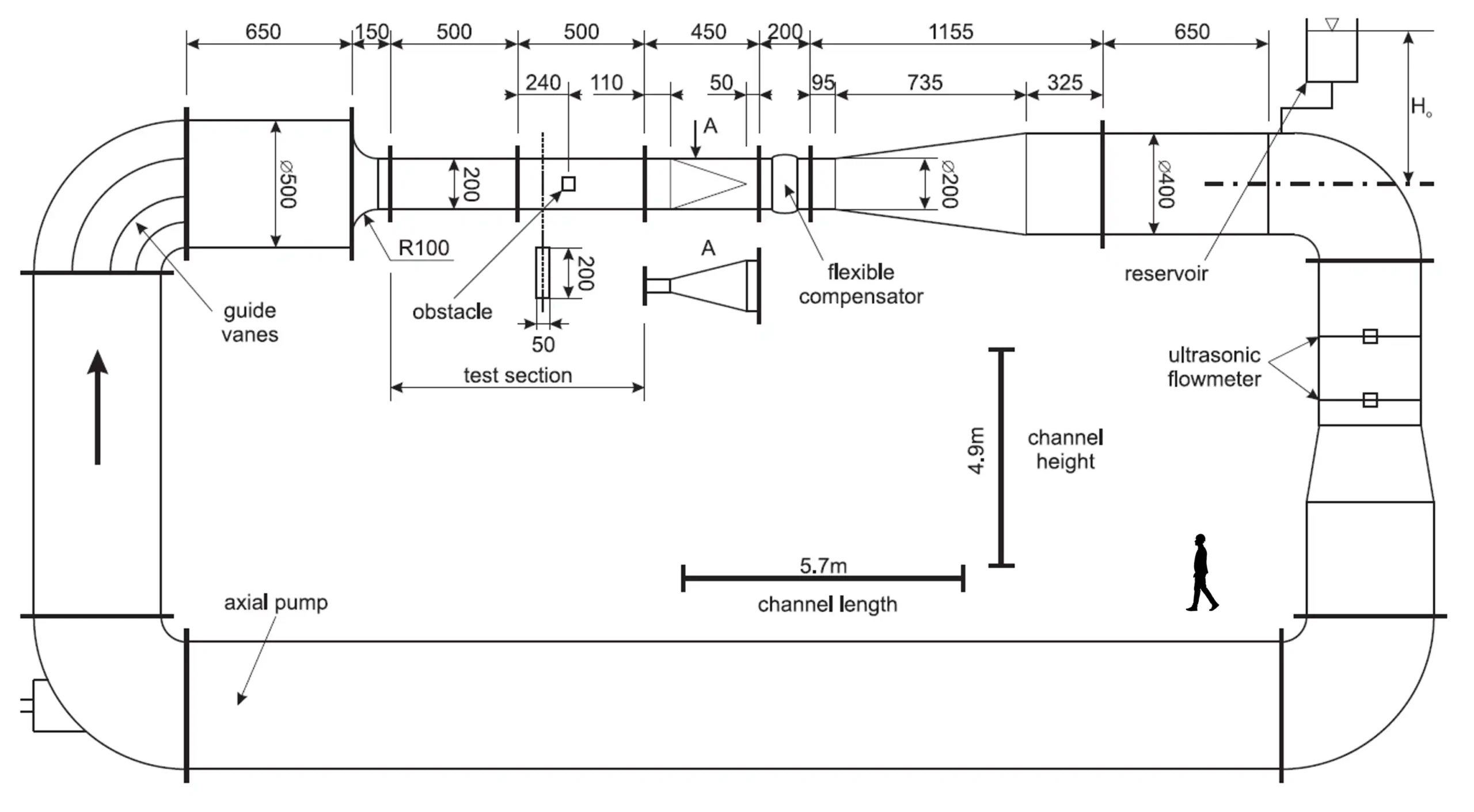

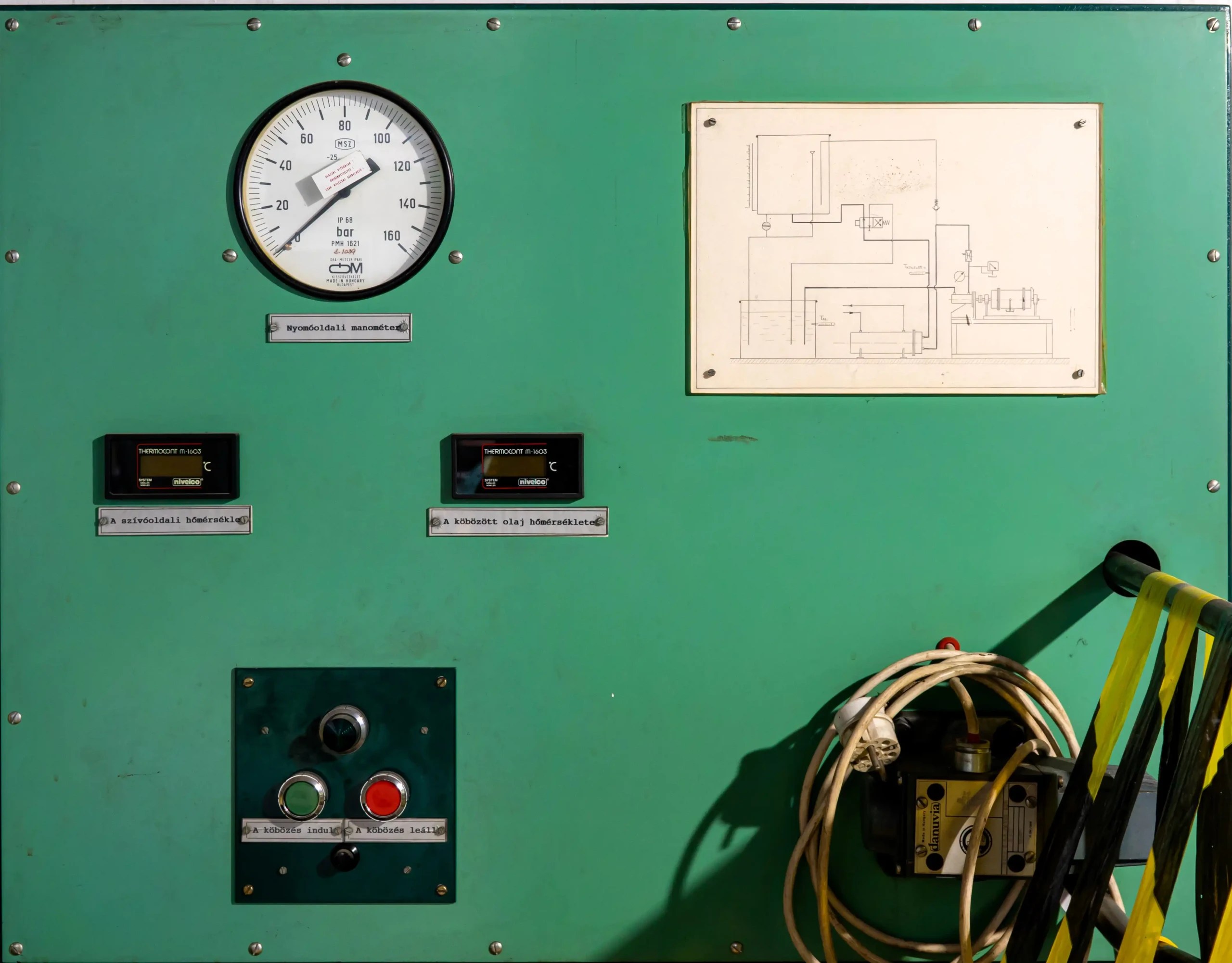

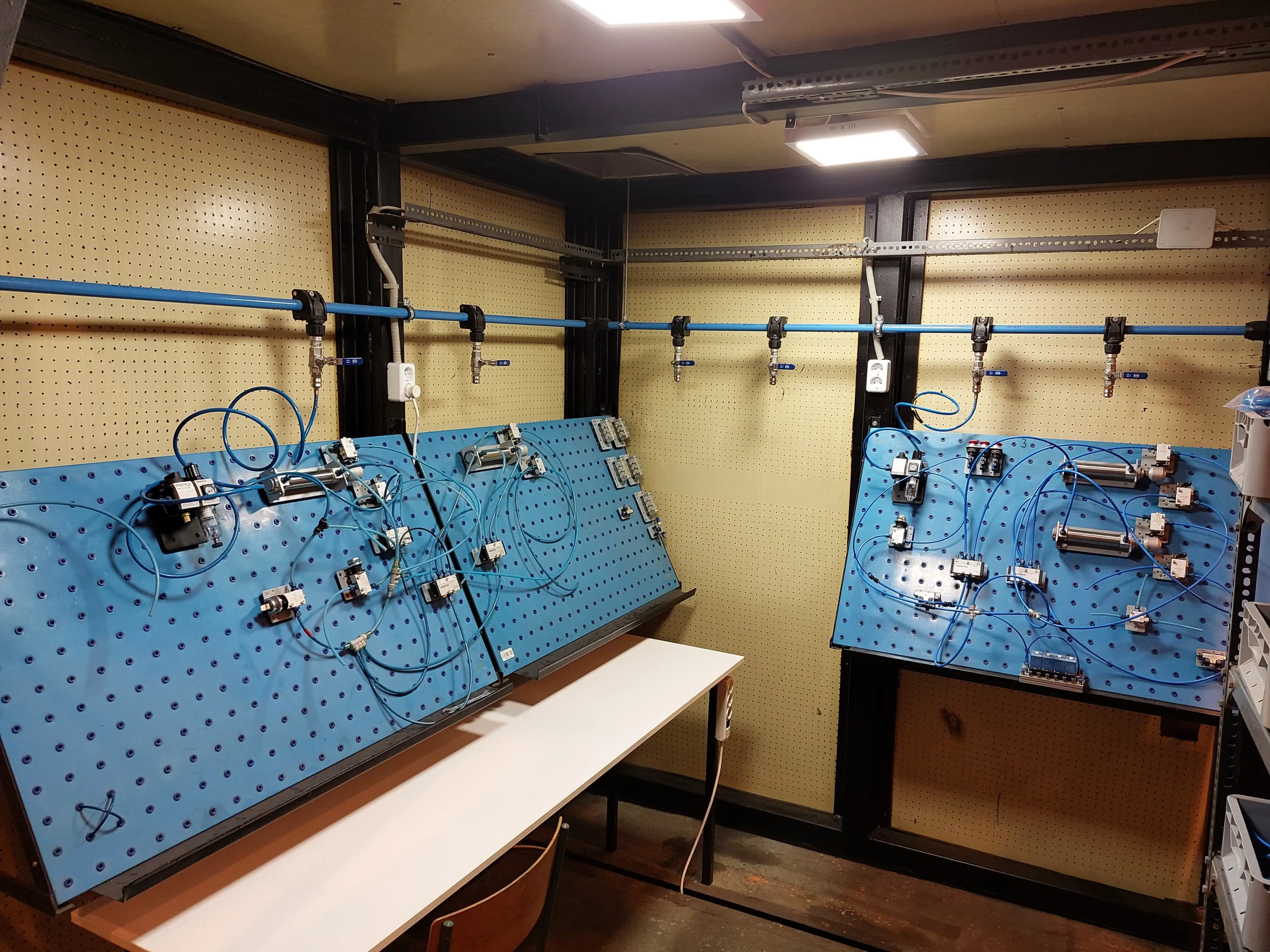

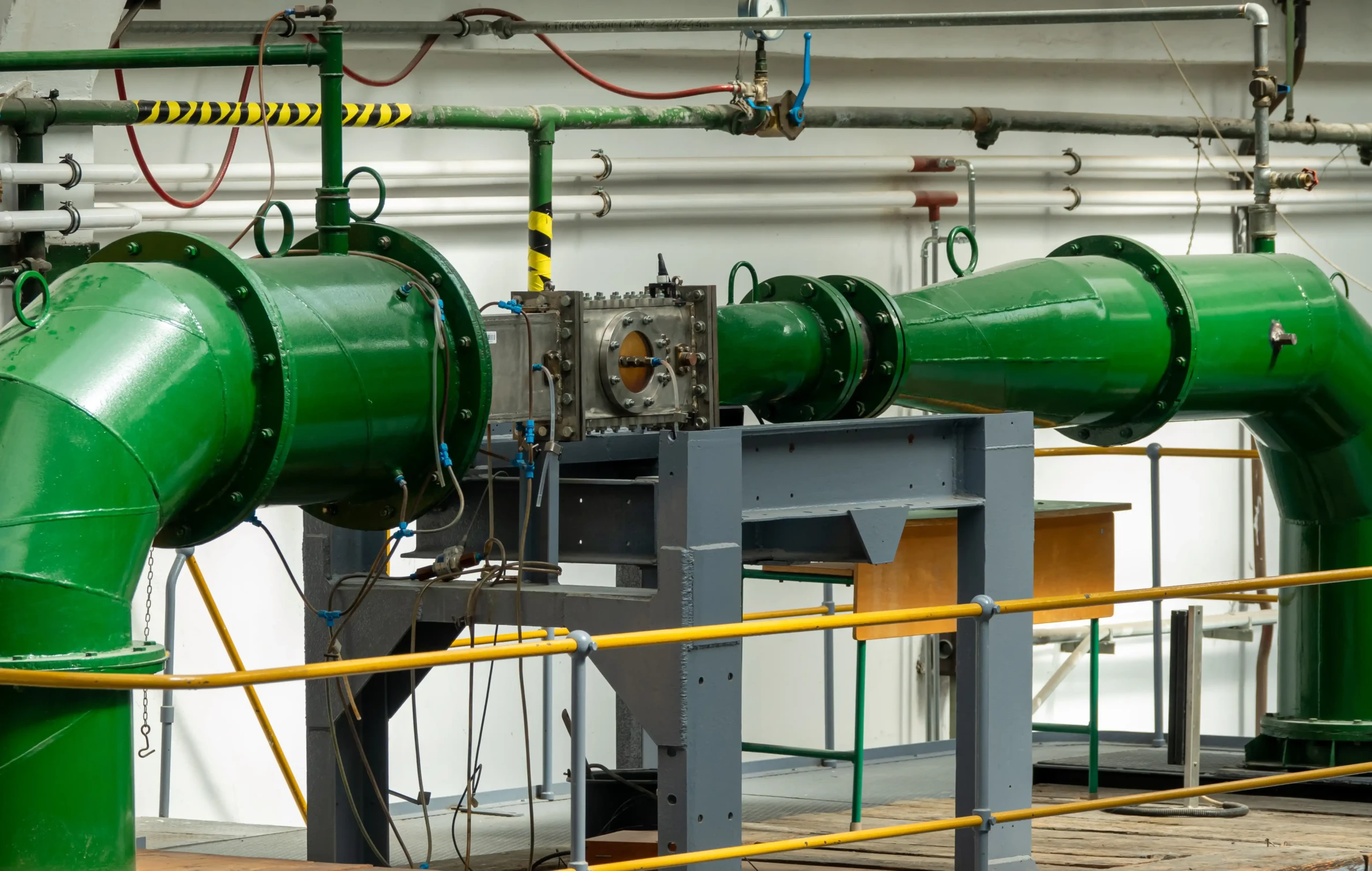

Our laboratory is equipped with several water pipeline systems of various sizes, as well as open-surface water channels and tanks, offering a wide range of measurement and testing possibilities. In addition, hydraulic and pneumatic test benches allow for the examination of components, devices, and machines operating in oil and air media.

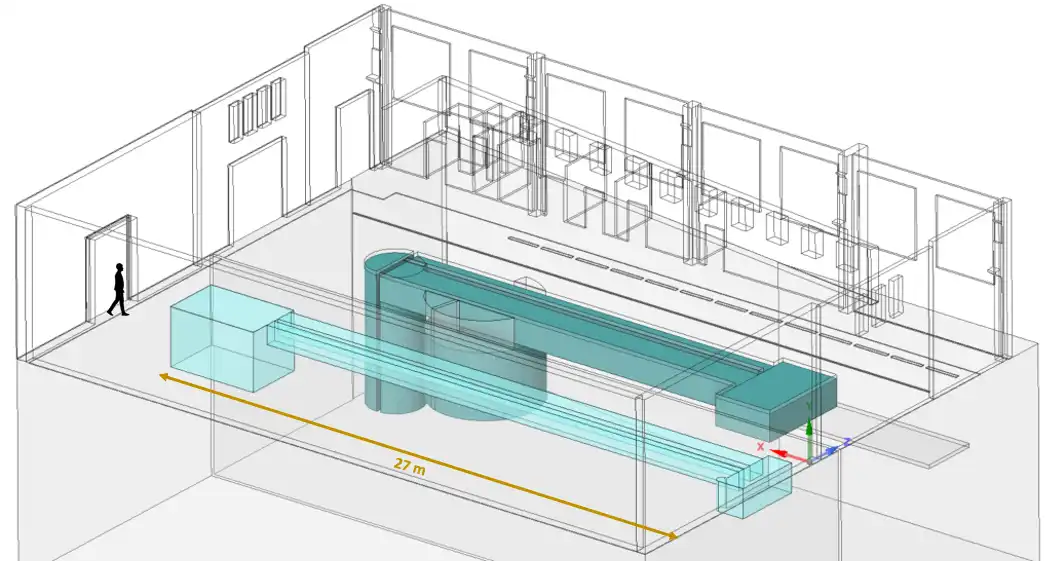

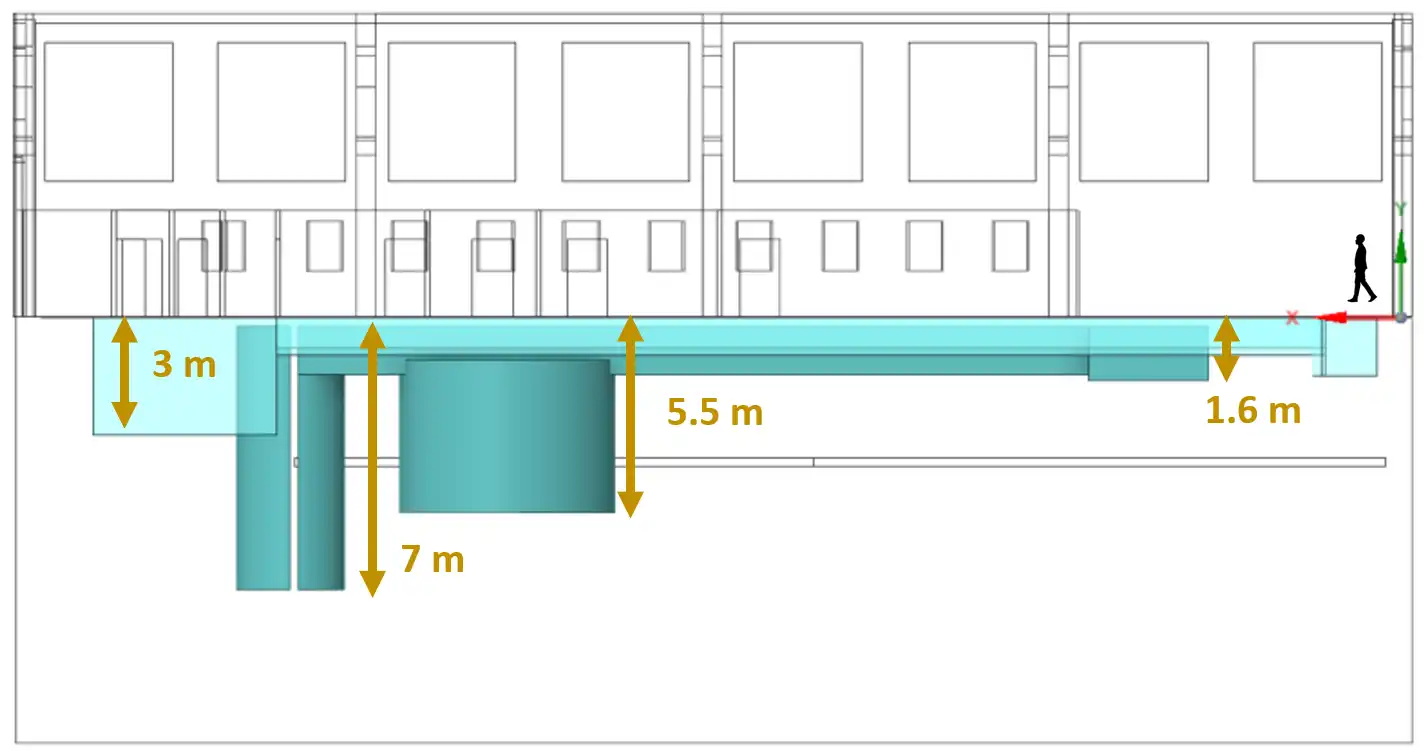

Large lab space

Nearly 1000 m2 of floor space and a significant interior height of 6-10 m enable the construction of large-scale measuring equipment.

High-performance electrical network

Thanks to the 630-amp power supply, electrical equipment with a capacity of up to 200 kW can be operated.

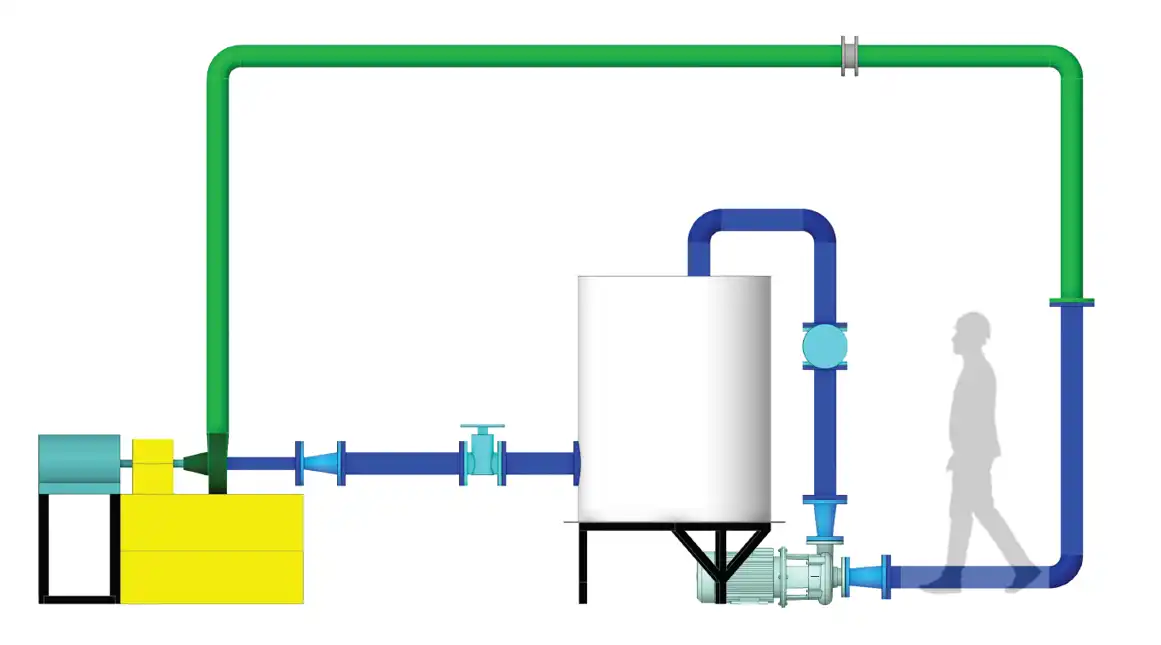

Closed water circuits

Measurement options:

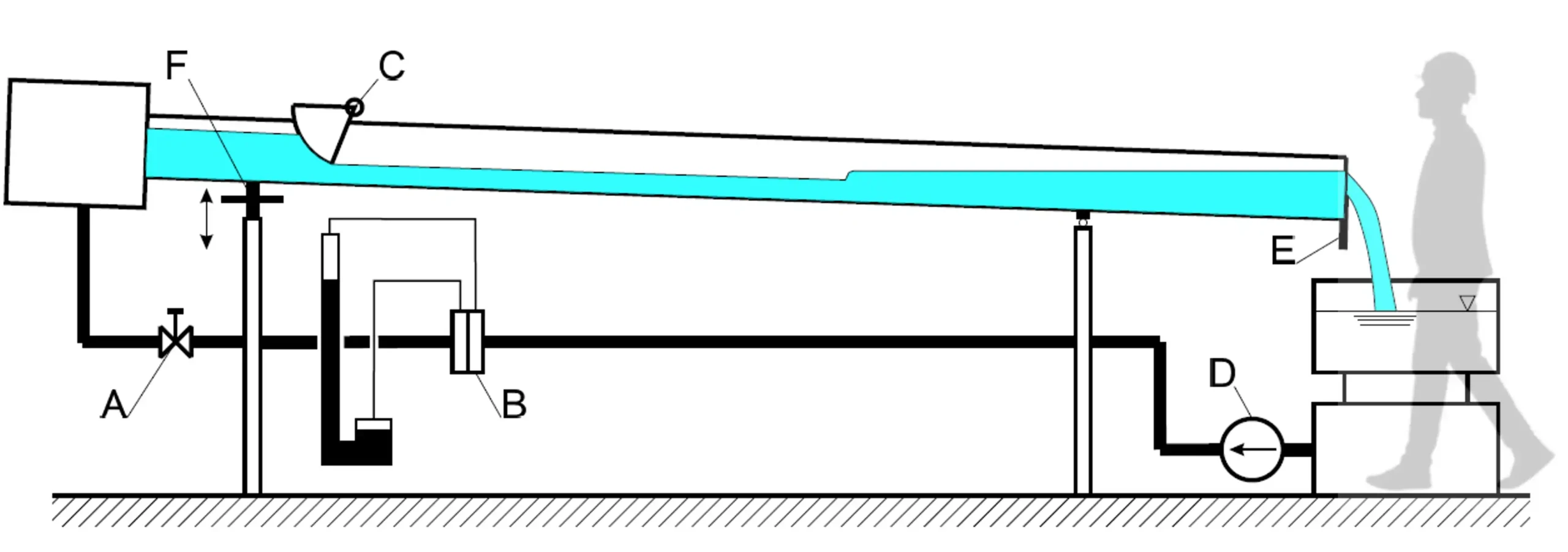

Open water circuits

Measurement options:

Measurement benches

Measurement options:

Measurement technology

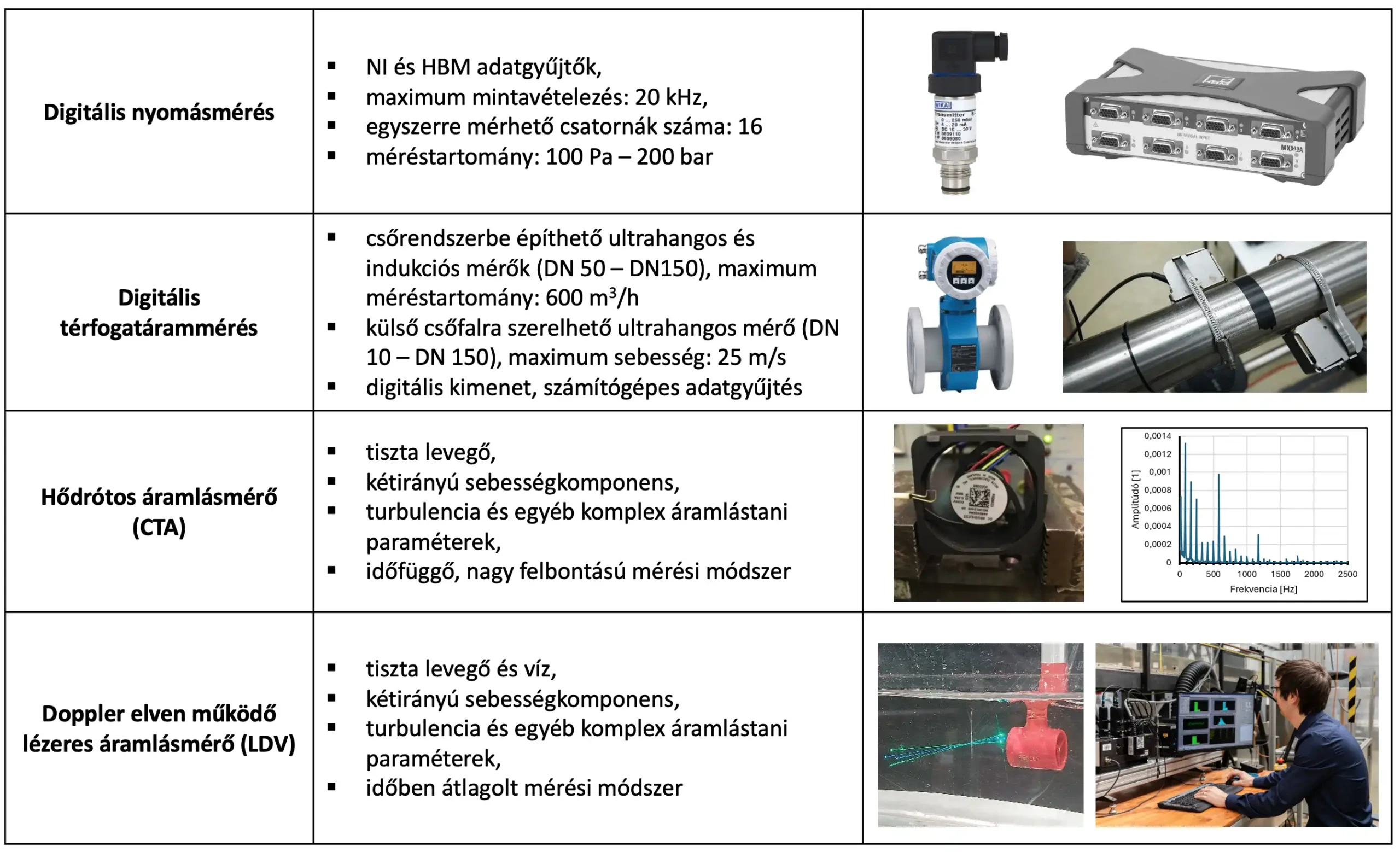

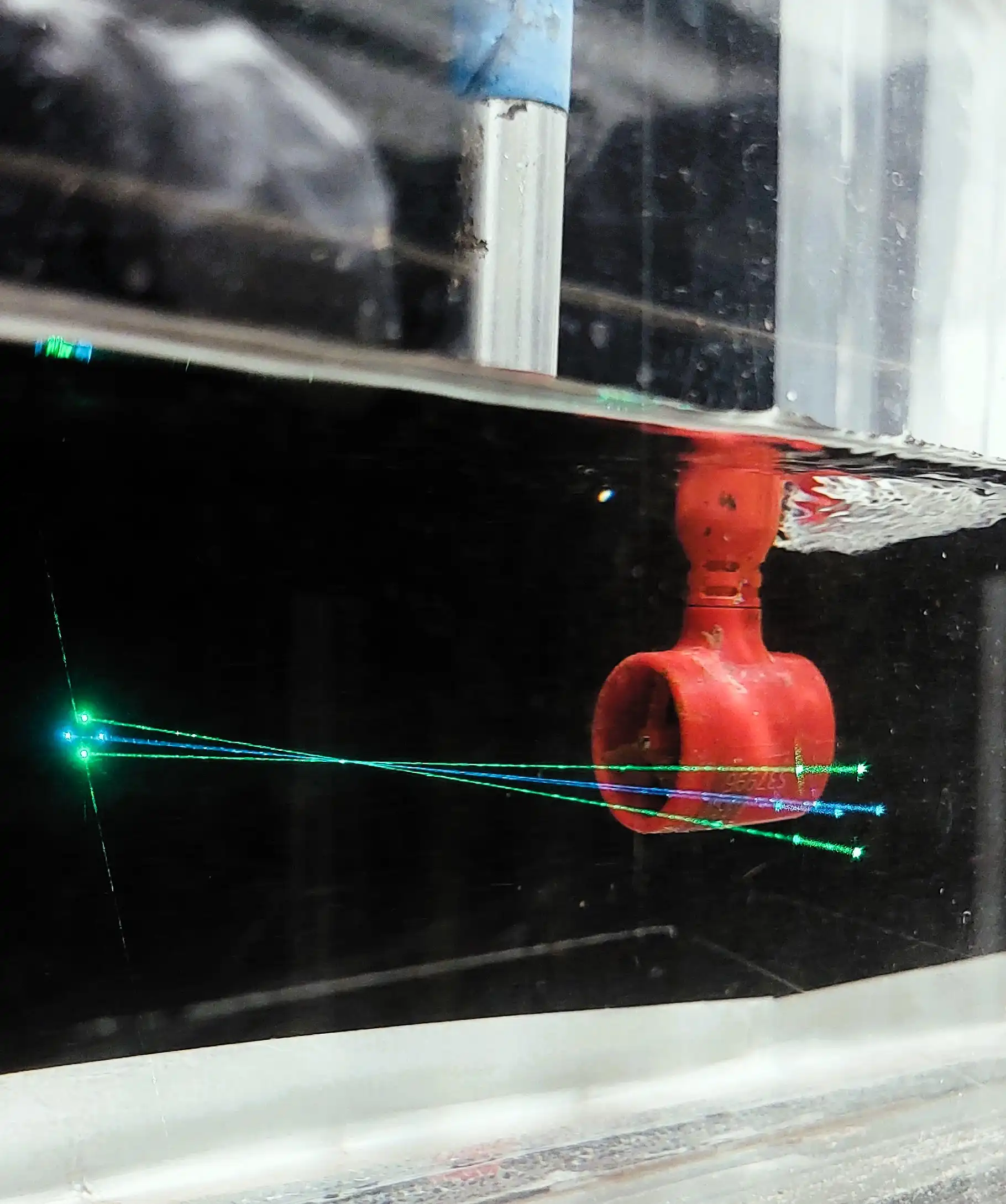

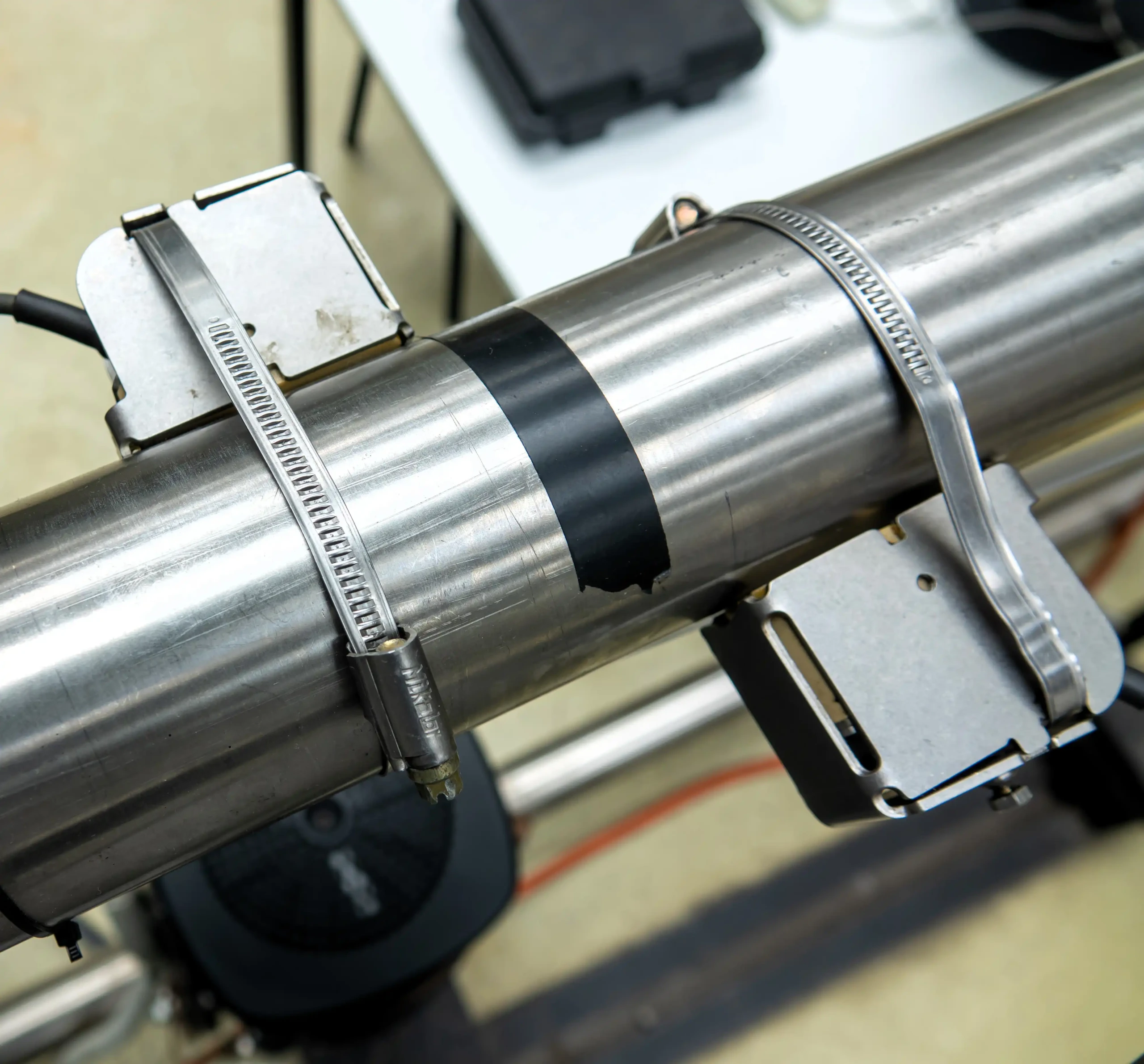

During measurements, we use both simple analog instruments and modern digital devices. With our custom-built measurement systems — consisting of sensors, data acquisition units, and measurement software — we can perform time-dependent pressure and flow rate measurements, including on external sites when needed. For measuring flow velocity, turbulence parameters, and visualizing flow structures, we also use advanced laser Doppler (LDV) and hot-wire (CTA) flow measurement systems.

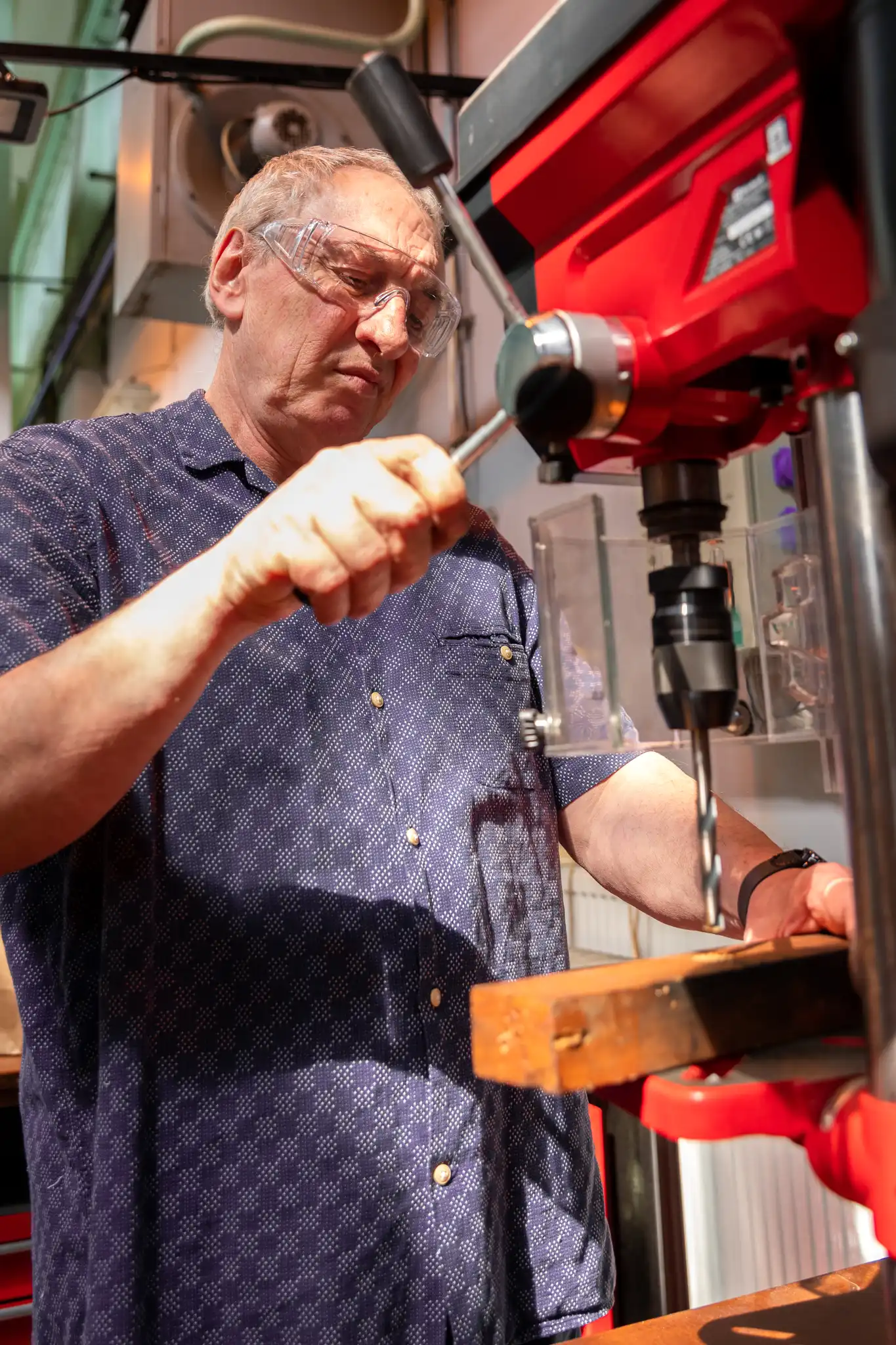

Workshop for production and product development

An essential part of our laboratory’s work is the regular maintenance of measurement equipment, as well as the design and construction of new measuring systems, either for internal use or in collaboration with industry partners. This activity also includes in-house manufacturing, supported by two conventional lathes, a multi-axis milling machine, drilling and grinding machines, and two 3D printers.

The laboratory employs two full-time technicians to support manufacturing and assembly work, including electrical tasks. Assembly processes are aided by 2-ton and 5-ton overhead cranes, which allow us to safely handle and move heavy machinery. Thanks to the large laboratory space, we are also able to manufacture large-scale support structures as part of our production activities.

Contact

Lab

1111, Budapest, Bertalan Lajos Street 7.

info@hds.bme.hu