With decades of experience, we support our partners in solving complex engineering problems.

With decades of experience, we support our partners in solving complex engineering challenges. Using measurement techniques and mathematical modeling methods, we provide a detailed analysis of fluid dynamic and engineering processes. Once the problem is understood, we develop potential solution strategies, which we validate through small-scale experiments or numerical simulations. This approach has already enabled us to deliver reliable and innovative solutions to a wide range of operational and product development challenges.

Our competences

Our Department has a long tradition in flow measurement techniques, general mechanical engineering measurements, classical mathematical modeling, and in some cases analytical solutions. In addition, we apply state-of-the-art numerical flow simulations and modeling methods, which we validate with laboratory experiments whenever possible. With a laboratory space of about 900 m2 and a dedicated technical staff, we carry out the complete process of designing, manufacturing, assembling, testing, and documenting both small- and large-scale experimental setups. These capabilities support research as well as industrial consulting and expert studies.

Our cooperating partners:

Our expert activities

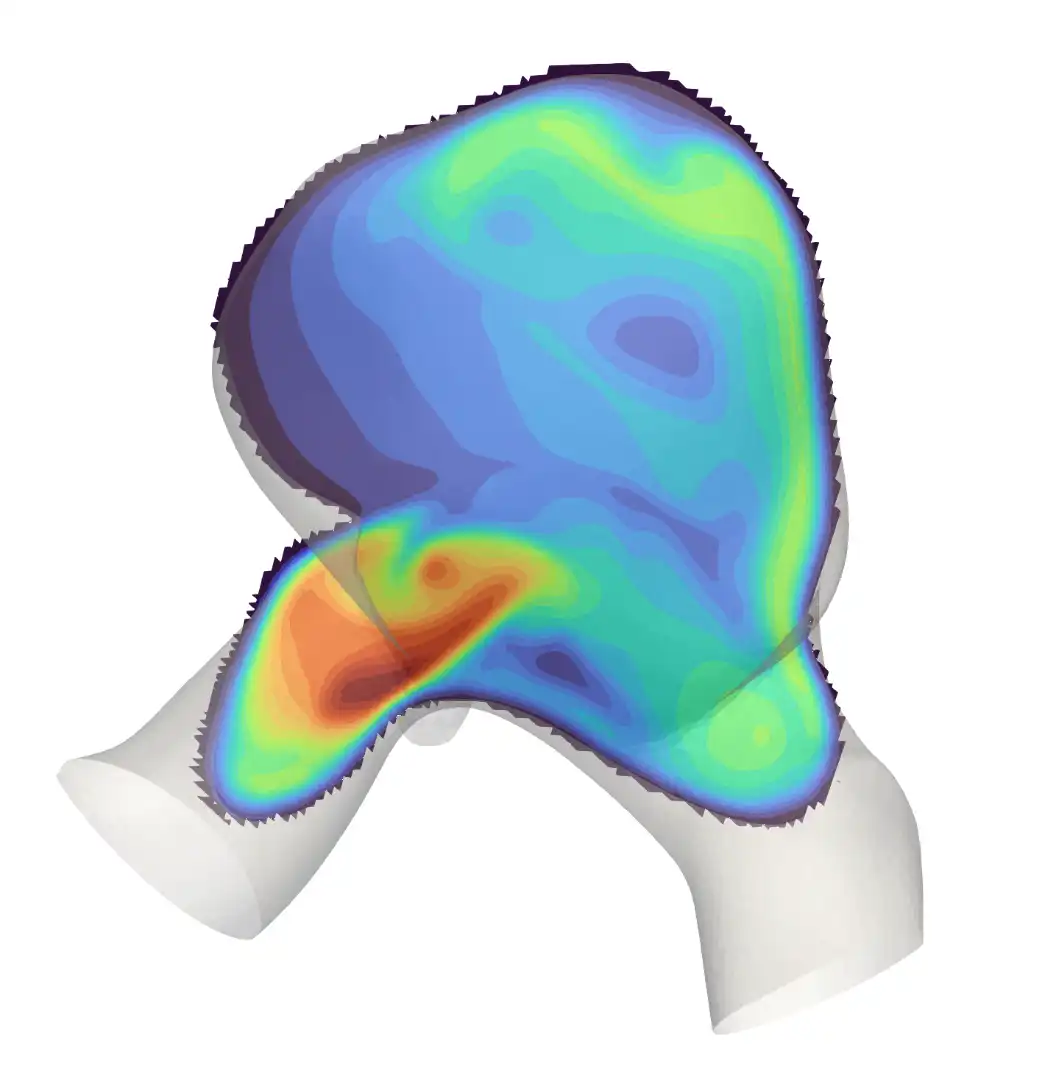

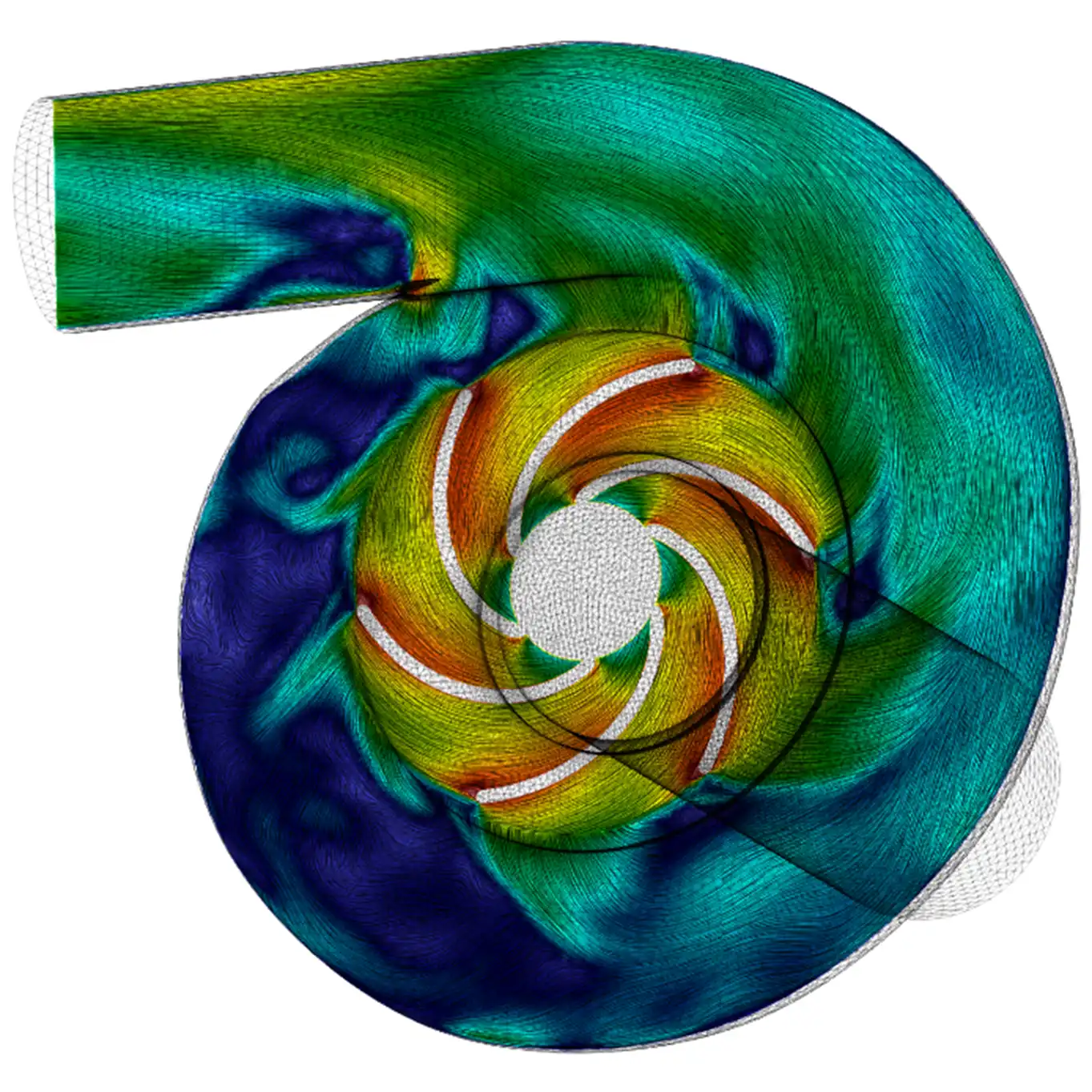

Fluid Dynamics Simulations – CFD

It is often a challenge to study the effects of geometrical and operational parameters solely through experiments, as the required manufacturing procedures can be costly and time-consuming. In addition, many flow structures, forces, separations, or heat transfer phenomena cannot be measured directly or made visible in practice.

In such cases, we apply numerical flow simulations – Computational Fluid Dynamics (CFD) – which can be flexibly used to address a wide range of industrial problems.

Our expertise includes, among others:

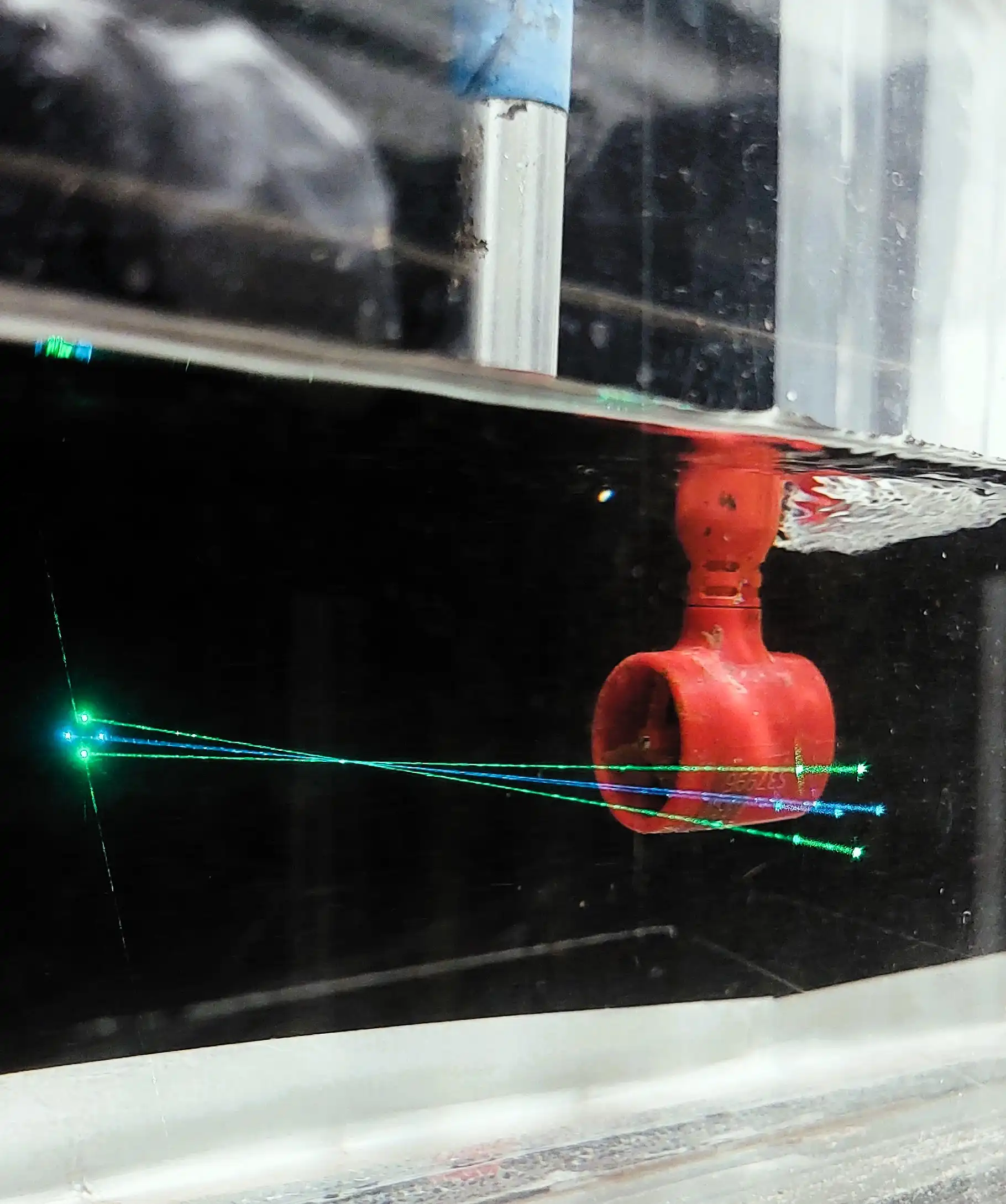

Flow measurement technology

Reliable measurements are essential for an accurate understanding of the operation of a device. Our infrastructure allows for both laboratory and on-site testing. Our laboratory, with a floor area of over 900 m², has two free-surface water pools with a total volume of 60 m³, as well as a built-in pipe network system, making it suitable for testing numerous elements of fluid engineering systems.

We use high-precision pressure transducers and flow meters for measurements, and the received signals are analyzed with an advanced signal processing system. Our in-house measuring devices enable on-site, time-dependent pressure and flow measurements, even with real-time data processing. A modern Laser Doppler Anemometer (LDA) is also available to determine local flow velocities.

We can perform the following types of tests with our measuring systems:

Product development

When developing a new product, established methods often cannot be applied, which makes the theoretical background especially important. To create the best possible prototype, we combine analytical approaches with numerical simulations, resulting in a simplified so-called reduced model. This model can reliably predict system behavior.

Using the model and considering various parameters such as performance and cost efficiency, we carry out optimization to achieve the most effective design. If required, the prototypes designed in this way can also be manufactured in our own laboratory, where we verify their functionality and efficiency through measurements.

Our expertise in modeling and optimization is confirmed not only by the feedback of our industrial partners but also by internationally recognized research results.

Measuring circuit development

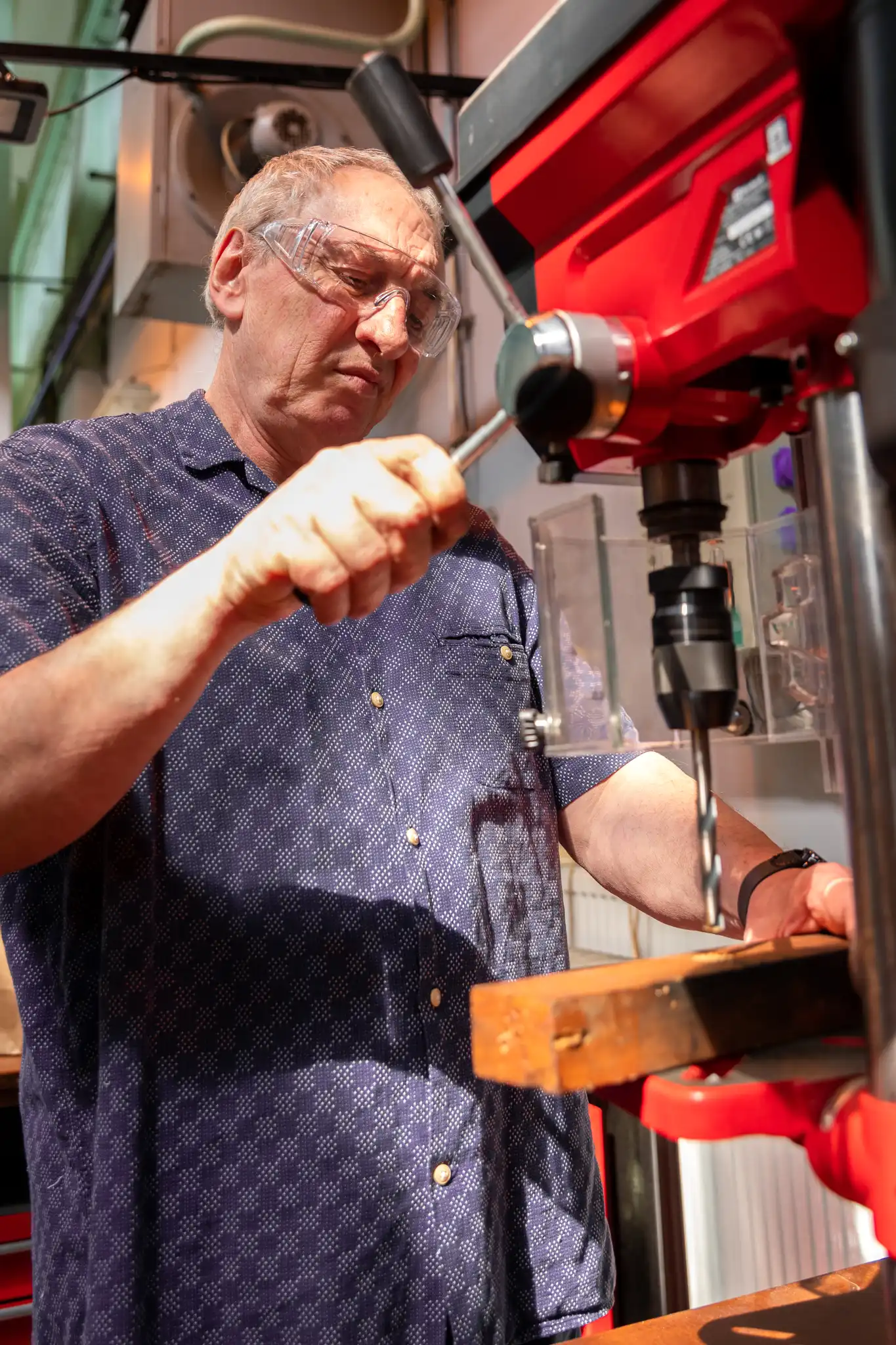

The development of innovative, custom solutions often requires specialized test systems. Our well-equipped laboratory workshop features milling, drilling, and lathe machines, enabling the production and assembly of unique testing setups. Experienced engineers design, manufacture, and assemble these new measurement systems tailored to the specific requirements of each client.

For each application, we select and procure the necessary sensors and data acquisition equipment. When needed, we also develop custom evaluation and data processing software, ensuring that the entire measurement chain is fully adapted to the needs of the project.

Laboratory

Hydraulic laboratory with high-performance measuring circuits

Our 900 m² laboratory area provides the opportunity to perform high-volume flow measurements with various media, such as water (e.g. gate valves, valves, pumps) and air (e.g. fans, air handling units). The laboratory also includes a well-equipped workshop suitable for rapid prototyping, where our qualified staff ensures the fast and accurate implementation of custom measurement systems.

There is also an oil hydraulic circuit and a large open surface water basin. With the help of our open surface water channel and cavitation channel, we can perform complex flow engineering tests. The high internal height of the lab allows the installation of individual measuring circuits, even in case of special installation requirements.

Our reference works

Stationary pipe network modeling

We have conducted steady-state pipe network modeling for several partners, using both our proprietary code (the Staci program) and the EPANET software. These calculations analyze the steady-state behavior of pipe networks, including branch flows, flow velocities, nodal pressures, water levels in open channels, water age (residence time), and chlorine concentration distribution. Additionally, our proprietary program runs as background support for our partner’s geographic information system, allowing the immediate assessment of any operational changes to the network through automatic simulation.

Partners: Budapest Metropolitan Water Works, Sopron Water Works Ltd.

Transient pipe network modeling

At the request of our partner, the Department examined the impact of large consumers on the hydraulic systems of Hungarian cities, focusing especially on transient phenomena in the planned water network. The modeling was divided into two main parts: the sudden shutdown and startup of pumps, and the abrupt cessation of industrial consumption. Special attention was given to the minimum (below atmospheric pressure) and maximum (>10 bar) pressure levels occurring in individual pipelines. In the first case, infiltration (contamination from groundwater), pipe collapse, or even fluid column splitting may occur, while high pressures can lead to pipe bursts. These studies were carried out using computer simulations.

Partners: FŐMTERV Engineering Design Ltd., Sopron Waterworks Ltd.

Pump impeller shape optimization

The energy consumed by fluid machinery represents a significant portion of the world’s total energy production, so even small improvements in efficiency can lead to substantial global energy savings. Moreover, the geometric design can be optimized not only for water but also for specialized fluids, including those with non-Newtonian rheology. In our related research, we have carried out measurements and numerical simulations to study and optimize the design of pump impellers for water applications.

Partners: Grundfos South East Europe Ltd., Elpumps Ltd.

Kayak paddle development

In elite sports, the technical characteristics of the equipment used can be as important as the athlete’s performance. For our partner, we developed a kayak paddle geometry with improved hydrodynamic properties compared to those currently available on the market. This was achieved through numerical flow simulations combined with laboratory measurements for validation.

Partner: Best Paddle Sports Equipment Manufacturer and Distributor Ltd.

Testing of pipes, pipe fittings, and flow measurement systems

The primary purpose of testing flow components and fittings is to ensure compliance with the applicable national standards and to independently verify the data provided by the manufacturers. In addition, our laboratory performs loss coefficient measurements, as well as leakage and pressure tests, on behalf of our partners.

Partners: Euroflow Zrt., Kristály Kft., Elpumps Kft., Ometrys Kft., ASG Kft.

UV water purifier – disinfection equipment design

As a result of our research and design work, a custom-made UV water purification system was developed for the Csepel drinking water treatment plant to complement chlorine-based water treatment. We conducted hydraulic and CFD-based dose calculations, as well as our own laboratory measurements to estimate the arrangement and intensity of the UV lamps.