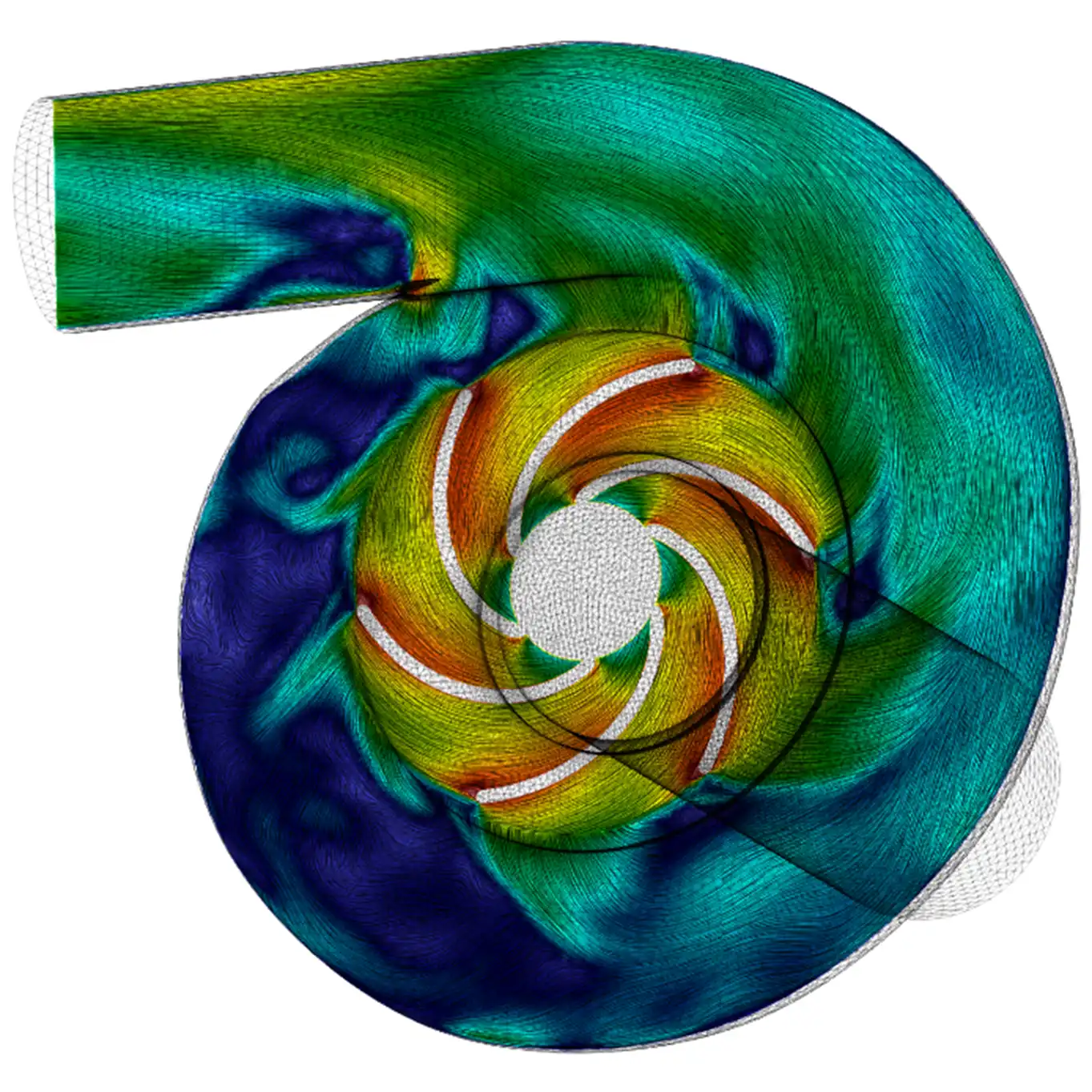

The hydraulic design of mechanical equipment transporting fluids is a particularly important engineering task, both for energy efficiency and operational safety, which is far from being mature in the case of non-Newtonian rheological fluids. The basic question is: how does the non-Newtonian rheology of the fluid influence the characteristic curves of pumps, piping elements, or shock absorbers in fluid engineering systems? How can be better, more efficient equipment design or operational methods for these special fluids developped?

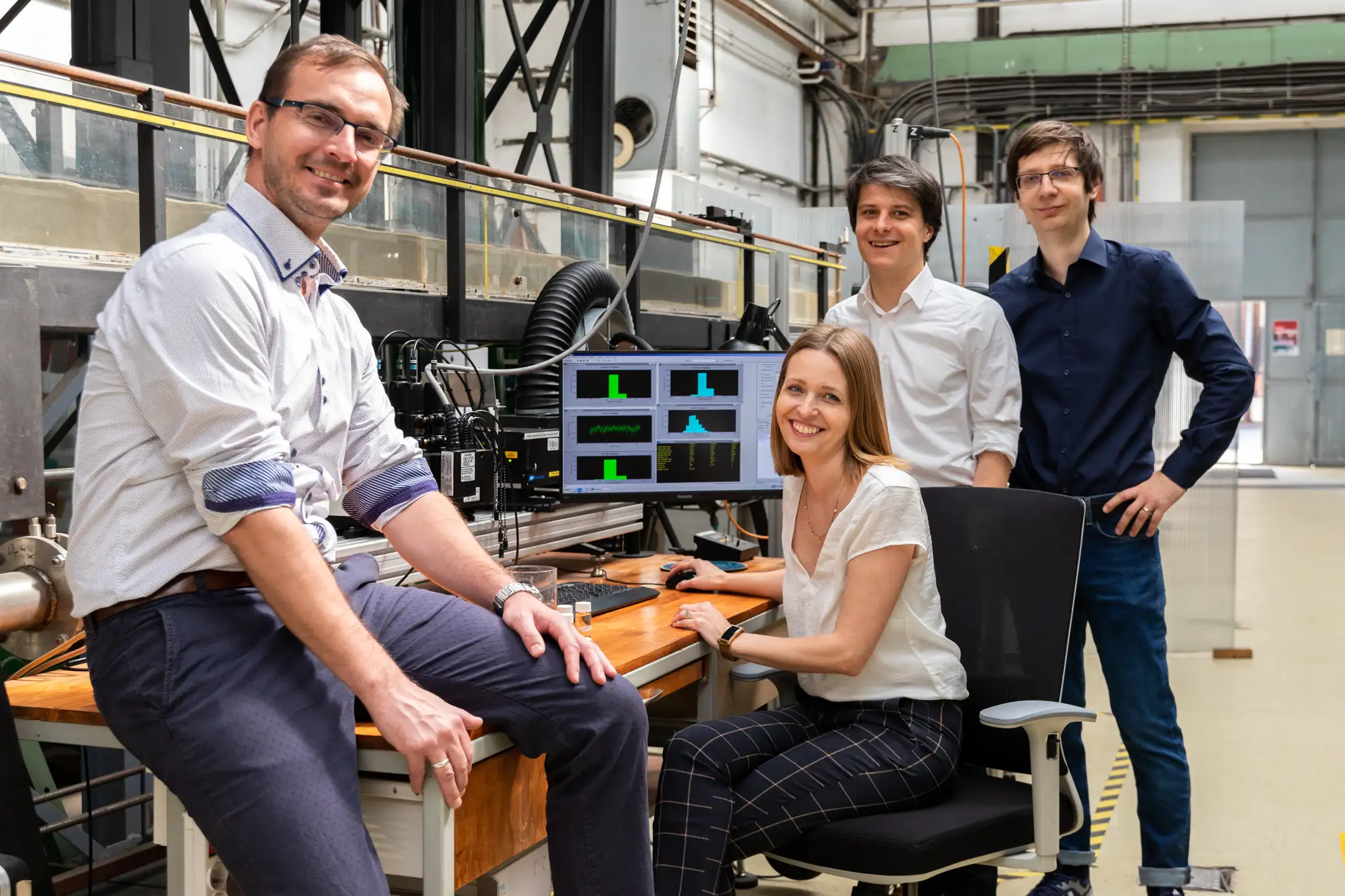

During the research, laboratory models for fluids with different flow properties were built and tested. Furthermore, based on these measurements and analytical approximations, inhouse numerical flow simulations, CFD codes were created, in order to be able to gain insight into complex flow structures.

Our research areas

Modeling of fluids with special rheology

Pumping non-Newtonian fluids

In many places in industry, non-Newtonian fluids are pumped in pipeline systems in many places, such as activated sludge in wastewater treatment plants, drilling fluid in oil drilling, or various fruit pulps in the food industry. On the one hand, we set ourselves the goal of determining the hydraulic resistance of pipeline system elements, not yet being clarified in the literature. On the other hand, we investigate the degradation of the characteristic curves of the pump delivering the fluid. In both areas, we prepare our own laboratory measurements and CFD computations validated with measurements. In this way, we rely on experimental work, and in addition, we can support and refine the sizing methods by mapping the flow structure. By linking the modified pump and system characteristic curves, we can provide designers with directly usable aid concerning safe operating points and specific energy consumption.

Development of shock absorption systems

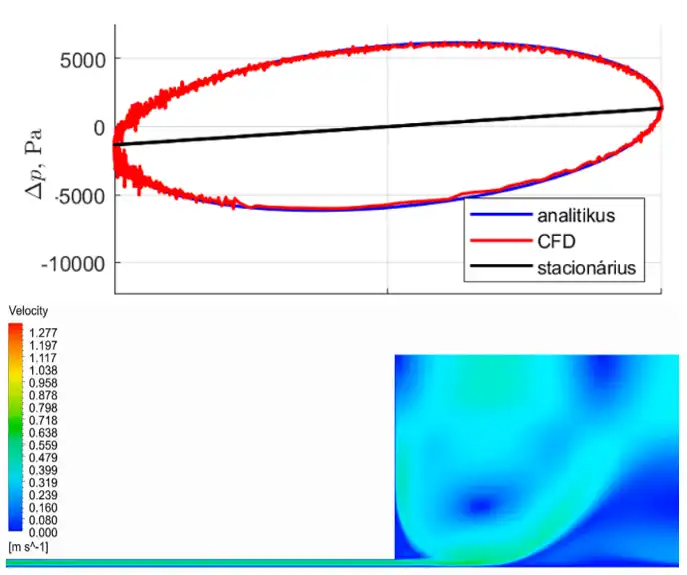

Rheology and geometry optimization

The main application area of non-Newtonian fluids in mechanical engineering is shock absorber systems. The base fluid (e.g. water and glycol derivatives) and solid particles (e.g. corn starch, silica nanoparticles) form shear-thickening suspensions, with abrupt viscosity increase under rapid and high loads, thereby creating a significant energy absorption capacity. During the course of our research, we develop a generally applicable design method that can be used to determine the composition of the fluid and the geometric dimensions of the damper for any damping requirement. We develop design tools based on computational fluid dynamics (CFD) and simpler analytical models, and the validation and fatigue tests are performed with an in-housemeasurement system.

Modeling flows in mixing tanks

Definition of mixing parameters

Mixing tanks are used in many areas of the chemical and pharmaceutical industry, ranging in size from 0.5 liter to 1 m3. Together with colleagues from the Faculty of Chemical Engineering and Bioengineering, based on the results of small-scale mixing equipment we are working on a scaling method that can be used to determine the parameters of large-scale mixing producing a similar end product. We are conducting our research together with a pharmaceutical company, in which we use the results of validated numerical flow simulations to train statistical models and predict the characteristics of large-scale processes. Our simulations require significantly fewer experiments, thus saving noticable development costs.

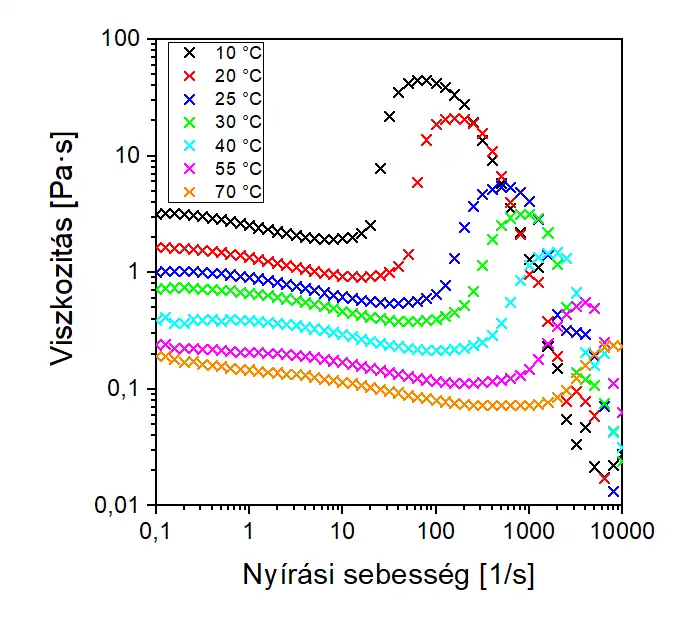

Fluid development

Rheological behavior of non-Newtonian fluids

This area of our research focuses on non-Newtonian fluids, especially dilatant, i.e. shear-thickening systems. The main goal is to produce such fluids, to study their structural properties in detail, and to analyze their rheological behavior using a wide range of experimental methods. We measure the viscosity of the fluids over a wide range of shear rates (0.01-10000 1/s) and also investigate the time-dependent viscoelastic properties. The parameters influencing the properties of the systems and playing an important role in industrial applications, such as particle morphology, concentration, and temperature are observed. The rheological studies performed provide a good basis for the precise adjustment of material properties in CFD models.